Advanced simulation and testing to validate structural safety

We complement structural analysis with FEM simulations and laboratory testing to ensure strength, reliability, and regulatory compliance.

Technical validation for materials, joints and components

We offer advanced simulation services and laboratory testing to complement structural calculations when required by the project. These tools allow us to anticipate the behavior of materials, connections, and components in critical situations, providing data that improves decision-making.

In this way, we help reduce risks, optimize costs, and ensure regulatory compliance, providing additional technical support for our calculations.

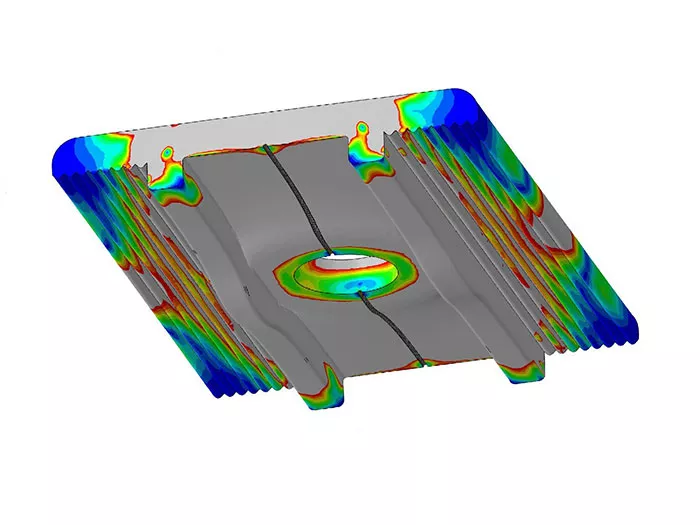

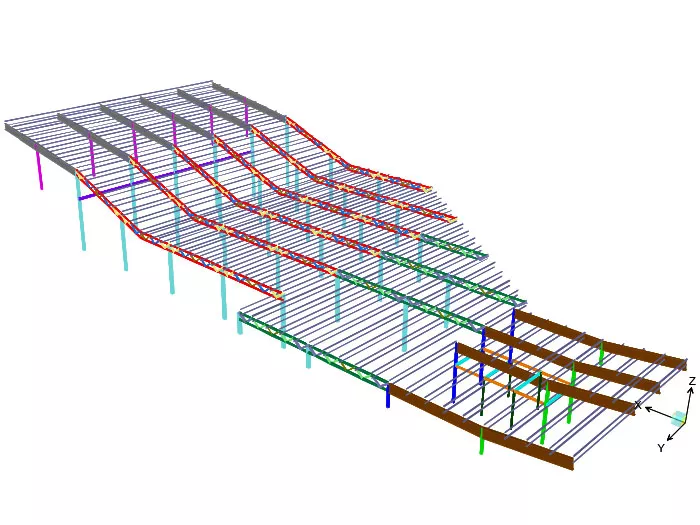

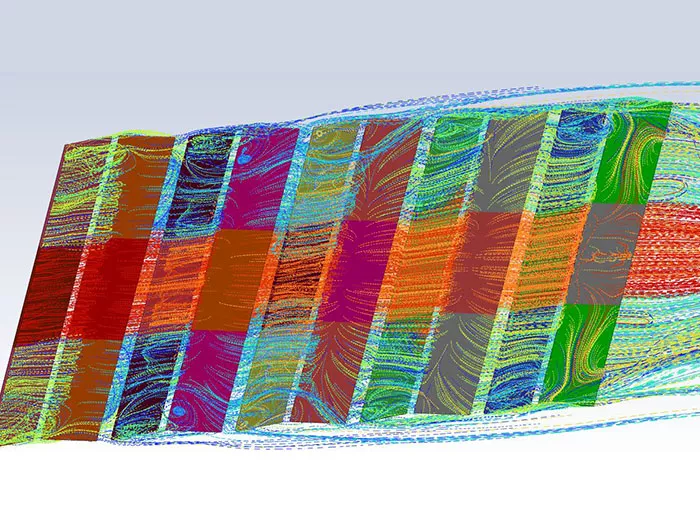

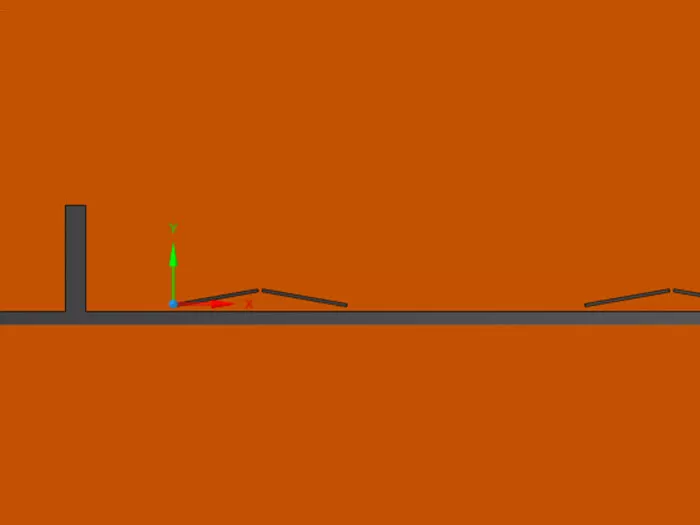

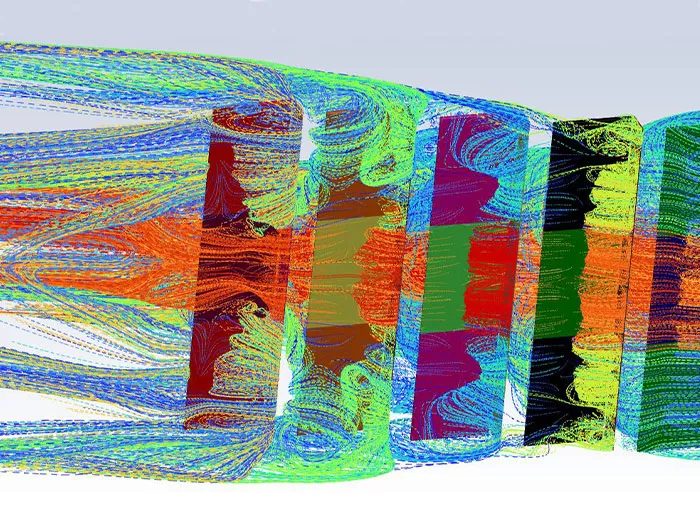

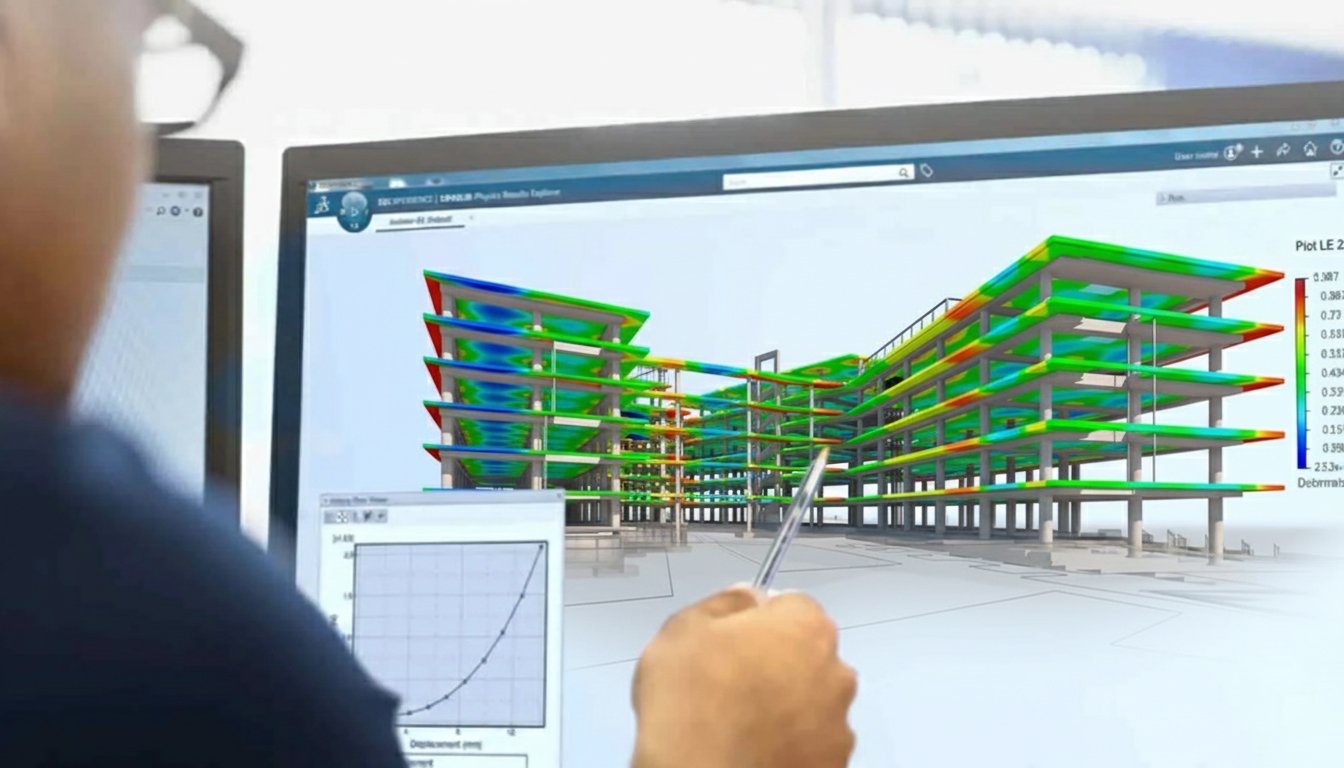

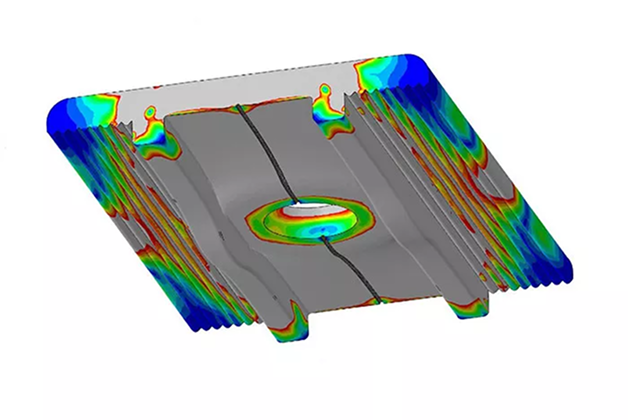

Finite Element Simulation (FEM)

We analyze the behavior of structures under extreme loads (wind, seismic, weight) to optimize design and ensure safety.

Request a quote

Mechanical laboratory testing

Physical testing of material and component resistance, deformation, and durability. We detect critical points and verify quality.

Request a quote

Certification

We issue technical certificates that attest to the regulatory compliance of the materials used in each project.

Request a quoteBenefits of working with us

Structural engineering with 15 years of experience and a team of experts in safe and optimized calculations.

Risk reduction on construction sites.

Design and cost optimization.

Regulatory compliance guaranteed.

Technical documentation validated by registered engineers.

Structural calculation and certification projects

Applied engineering in metal, concrete, aluminum, and photovoltaic structures.

Frequently Asked Questions

These are some of the most common questions from our clients. If you don’t find the answer you’re looking for, visit our FAQ page or contact us for further assistance.

Yes. A reproducible report and a clear certificate facilitate processing and shorten approval/purchase cycles, in addition to reducing uncertainty on site.

We apply CTE and Eurocodes (and specific client requirements). The report includes assumptions, ULS/SLS combinations, acceptance criteria, results, recommendations and, if applicable, a certificate.

Yes. We coordinate the necessary mechanical tests to validate hypotheses or prototypes. We define the test plan (procedure, samples, loads) and integrate it into the final report.

Plans or 3D/BIM model, description of use and loads, material, and types of connection; if there are regulatory or testing requirements, please indicate them. With that, we provide a technical quote and an approximate deadline.

For PV projects, we usually start from regulatory load combinations, and when required (parapets, edges, east–west layouts, suction), we integrate wind simulations to refine pressures and anchoring. (CFD is used only when it provides real value to the design.)

When there are unique geometries, critical joints, aluminum components (sensitive to buckling), or significant wind loads (rooftop/ground-mounted PV systems). FEM simulation confirms safety and can reduce material use without compromising safety margins.

Do you want to validate joints, parts, or supports before manufacturing or assembly?

Request your technical quote and receive a response in less than 24 hours.

Spain

Carrer de Balmes, 243, 5 2 Sarrià-Sant Gervasi, 08006 Barcelona

Polígono Ind. Molí d’en Xec, Nave 2, 08291 Ripollet, Barcelona

+34 937 375 881